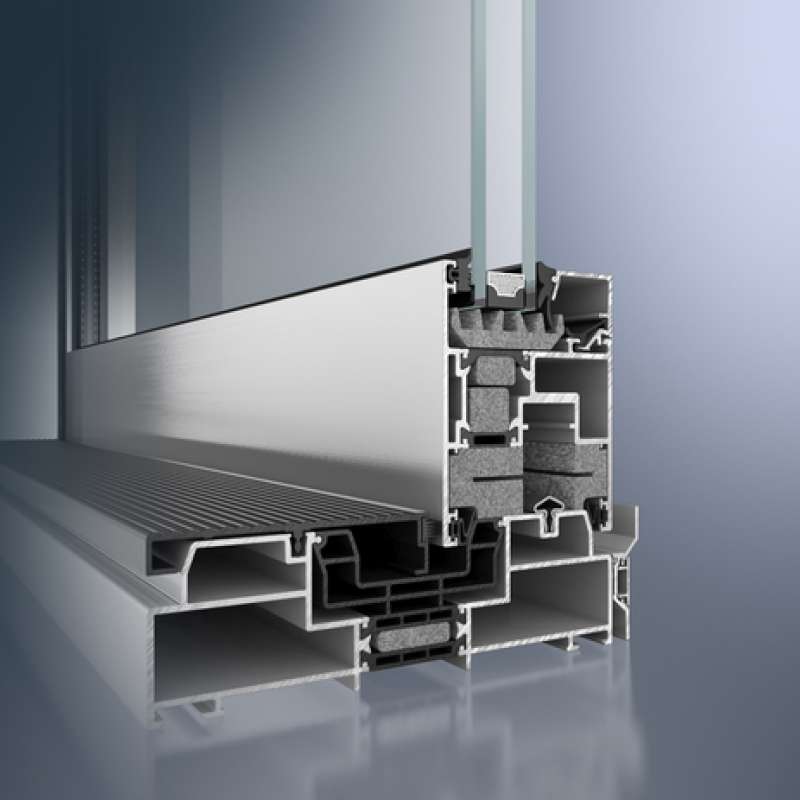

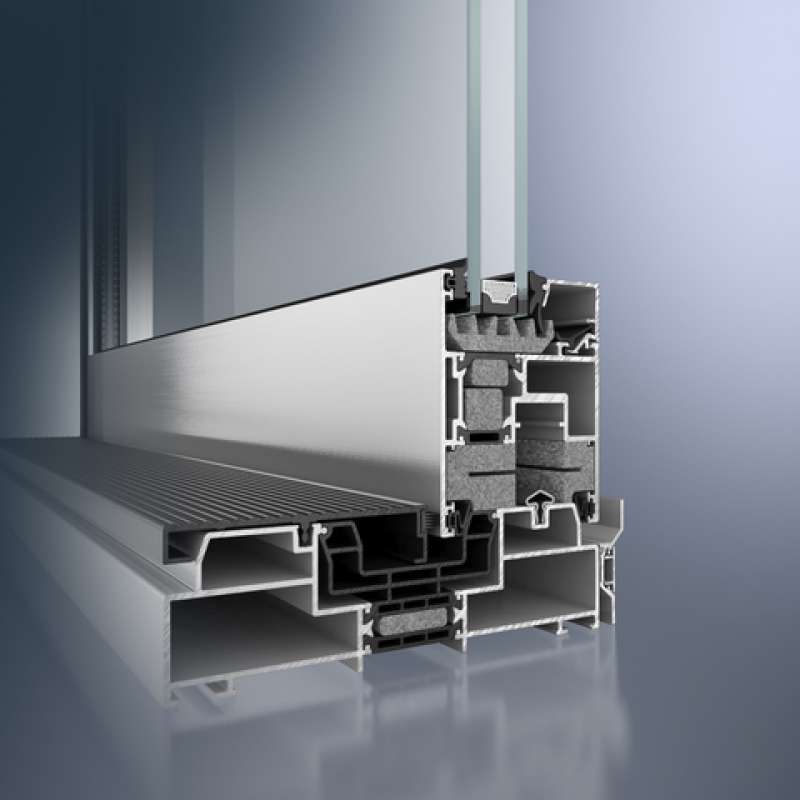

The highly thermally insulated sliding and lift-and-slide system with its perfect watertightness, excellent sound reduction, and burglar resistance up to class RC 2, is second to none.

The modular profi le insulation produces Uf values of 2.0 W/(m²K)and better, thereby achieving Uw values of < 1.3 W/ (m²K). Together with large opening widths due to single, double and triple track outer frames with very easy operation, the Schüco ASS 70.HI sliding and lift-and-slide system offers highquality system solutions for commercial projects and luxury homes

Product benefits

Uw values of < 1.3 W/(m²K), depending on the design

Excellent drainage system with watertightness up to 1,050 Pa

Sliding and lift-and-slide systems with optimised thermal insulation

Vent weight up to 300 kg, available for up to 400 kg special design

High-quality fi ttings components for easy operation

High degree of transparency due to large vent sizes of up to 9 m², depending on the design

Schüco ASS 70.HI, highly thermally insulated, aluminium, lift-and-slide door system

With 160 mm basic frame depth (double track), 250 mm basic frame depth (triple track).

Burglar resistance in accordance with DIN EN 1627, RC 2 (WK2).

Design features:

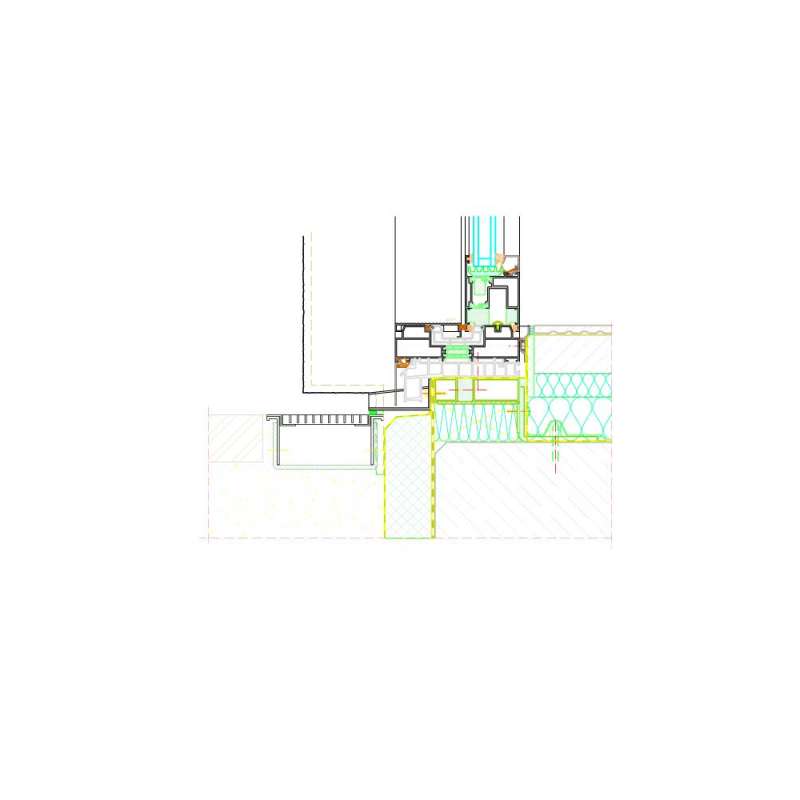

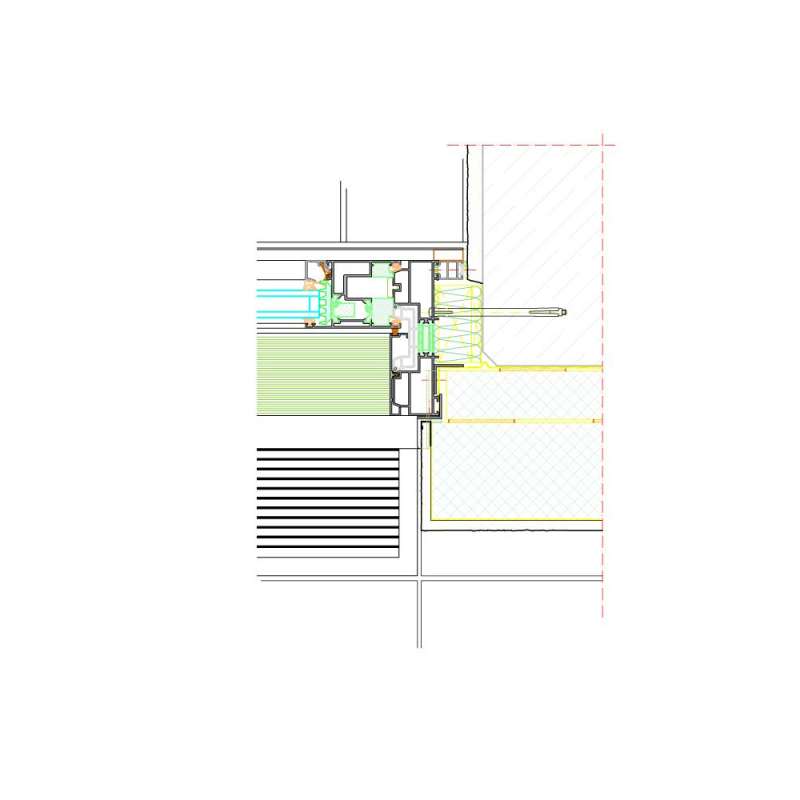

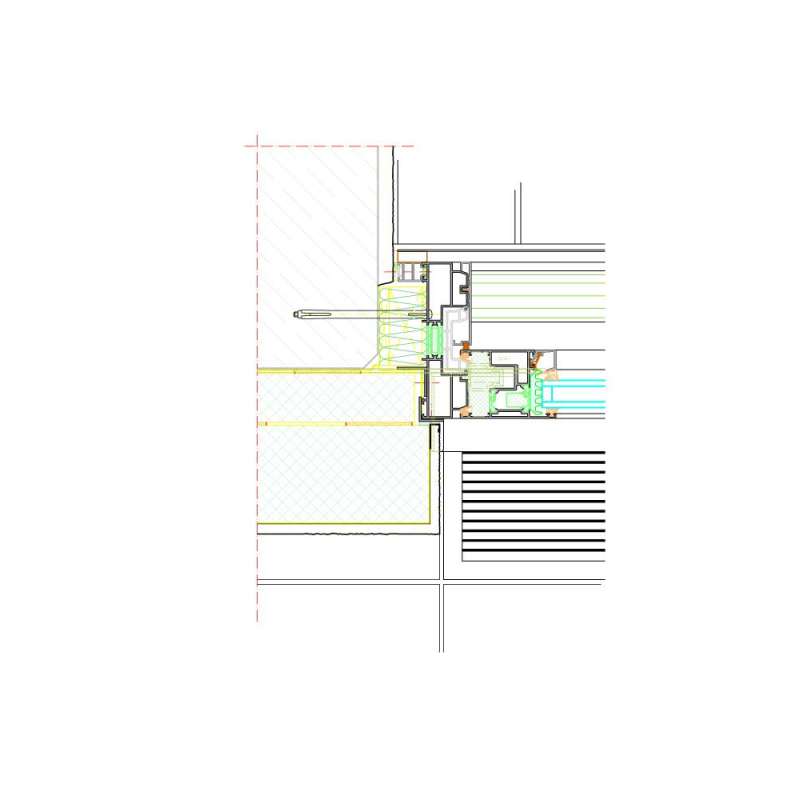

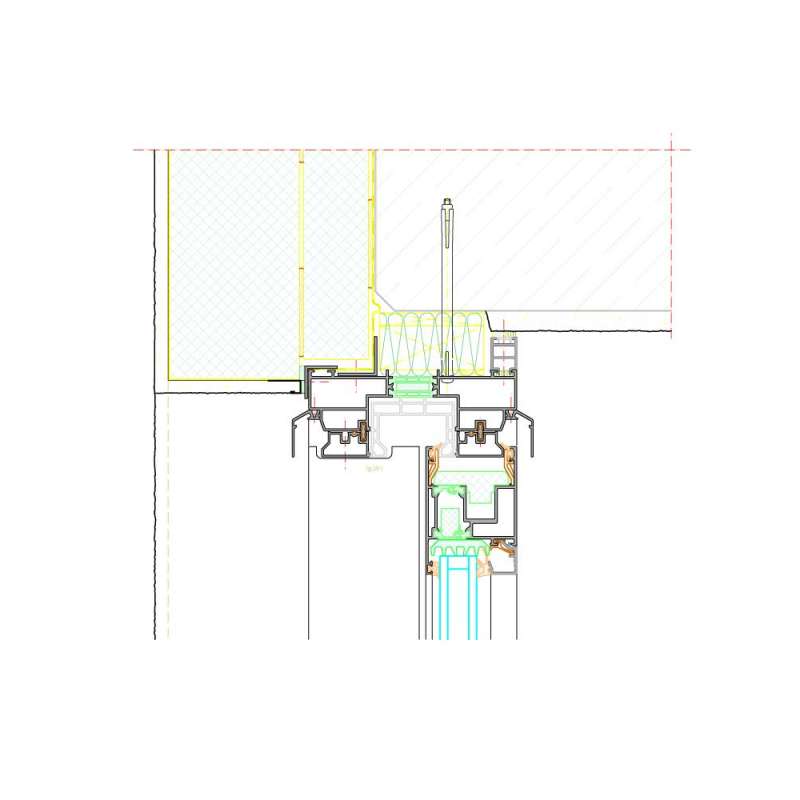

The outer frames with one / two / three stainless steel replaceable tracks are made with precision corner cleats, as are the vent frames.

In the joint area, the outer frames have plastic cover profiles on all sides.

The vent profiles and sash bars must be designed with one-part (fixed) / two-part (split) insulating bars.

Vent profiles with a classic contour for the weight classes 150 kg, as well as 300 kg and 500 kg, are available.

In the interlock sections, the vent frame profiles are designed with structural reinforcements to suit requirements.

Fixed glazing can be designed in the outer frame as fixed glazing, and as glazing in the fixed vent frame.

To achieve the "HI" values, glazing gaskets with fins must be used.

These gaskets are configured in such a way that they do not appear to the observer to form a broad border around the edge of the glass.

Glazing is carried out using glazing beads, which are inserted with aluminium clips to compensate tolerances.

In the double-vent area of the outer vent, a thermally broken glazing bead must be inserted with a plastic clip.

Profile basic depths:

Outer frame 160 mm single and double track / 250 mm triple track

Vent frame for both designs 70 mm

Vent sash bar, rebated 65 mm

Profile face widths:

Outer frame, continuous 31 mm

Vent frame with standard & SL contour 88 mm - 150 kg / 98 mm - 300 and 500 kg

Vent sash bar 88 mm